Chapter 5

RESULTS & A ; DISCUSSIONS

5.1 Consequences and treatments

This chapter shows the consequences of methodological analysis used to happen the CSFs, weightages of CSFs and barriers of Six Sigma execution in Indian car constituents fabricating industries.

5.1.1 Critical Success Factors of Six Sigma

Table 5.1 Gap analysis of CSFs of Six Sigma

Critical Success factors | Importance | Practice | |

A | Management engagement | 4.4 | 2.8 |

Bacillus | Organizational substructure | 3.9 | 2.5 |

C | Cultural alteration | 4.1 | 2.1 |

Calciferol | Education and preparation | 4.1 | 2.5 |

Tocopherol | Vision and program statement | 4.1 | 2.5 |

F | Associating Six Sigma to client | 4.2 | 2.4 |

Gram | Associating Six Sigma to concern scheme | 4.0 | 2.6 |

Hydrogen | Associating Six Sigma to employees | 3.8 | 2.9 |

I | Associating Six Sigma to providers | 4.0 | 2.5 |

Joule | Communication | 4.1 | 2.7 |

K | Understanding of Six Sigma | 4.0 | 2.9 |

Liter | Project direction accomplishments | 3.8 | 2.9 |

Meter | Undertaking prioritization and choice | 4.0 | 3.0 |

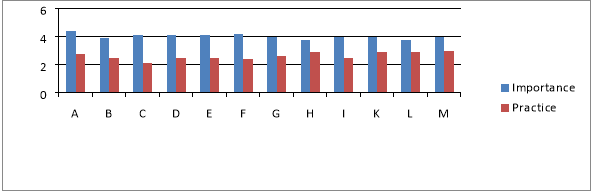

This undertaking work presents the consequences of the study conducted to place CSFs of Six Sigma within a medium graduated table car constituents fabricating unit and the consequences are used to compare with the findings of other research workers. The study consequence is represent the spread analysis revealed that there is the important spread between the sentiment of the employees of the company and the existent pattern of CSFs within the company. It is shown in table 5.1 and at that place graphical representation is shown in figure 5.1

Figure 5.1 CSFs of Six Sigma execution

- Consequences oforganisational public presentation

Table 5.2 Organizational public presentation standards to mensurate the success of Six Sigma

Organizational public presentation | Mean | Std. Deviation |

Productiveness | 2.2 | 0.8 |

Defects Reduction | 2.1 | 0.8 |

Warranty claim cost as a % of entire gross revenues | 3.1 | 0.9 |

Cost of quality as a % of entire gross revenues | 2.9 | 0.8 |

Delivery on clip to client | 3.5 | 0.8 |

Net income betterment | 1.5 | 0.8 |

Gross saless betterment | 1.7 | 0.7 |

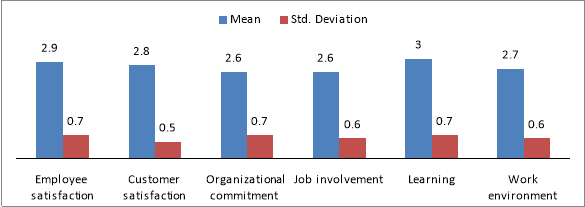

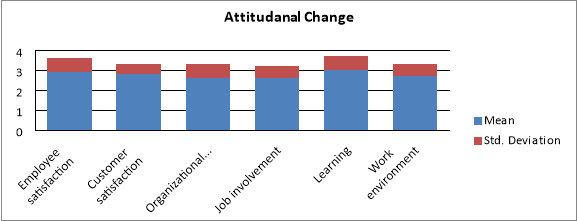

The consequences and benefits of Six Sigma execution within the administration were assessed in footings of organizational public presentation and attitudinal/perception alterations in the employees and clients. The organisational public presentation component of Six Sigma focuses on quality public presentation, operational and concern public presentation indexs, the inside informations of which are provided in table 5.2 and figure 5.2. attitudinal/perception alterations shown in table 5.3 and figure 5.3 that all the soft factors have got low evaluation from the respondents. The average values of factors are below 3, with occupation engagement and organizational committedness holding the lowest evaluation of 2.6. The highest evaluation of 3 for the acquisition factor shows that administration public presentation in footings of supplying preparation and coaching.

Figure 5.2 Graphical representation of organisational public presentation

Table 5.3 Attitude/Perception alteration after Six Sigma deployment

Attitudinal Change | Mean | Std. Deviation |

Employee satisfaction | 2.9 | 0.7 |

Customer satisfaction | 2.8 | 0.5 |

Organizational committedness | 2.6 | 0.7 |

Job engagement | 2.6 | 0.6 |

Learning | 3.0 | 0.7 |

Work environment | 2.7 | 0.6 |

Figure5.3 Attitude/Perception alteration after Six Sigma deployment

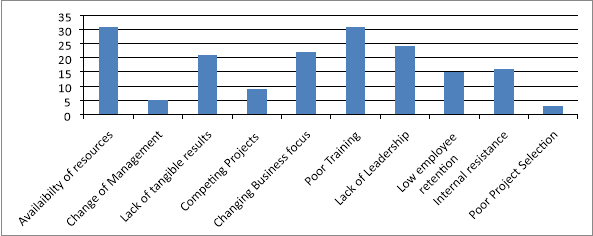

5.1.3 Impeding factors in the execution of Six Sigma

The respondents were asked to place three largest issues that they have faced during Six Sigma execution. Several obstructions to the acceptance of Six Sigma programme were highlighted as shown in figure 5.4

Figure 5.4: Factors suppressing the execution of Six Sigma

5.1.4 Consequences of AHP analysis

The AHP Analysis is performed to place the critical successful factor for Six Sigma execution in car constituents fabricating industries. For AHP attack 6 factors are selected, they are Education and Training, Associating Six Sigma to concern scheme, Cultural Change, Associating Six Sigma to client, Vision and program statement, Management Commitment and engagement. It is found that the Management engagement and committedness ( F ) has got highest weightage i.e. 0.2586 and it is in first precedence. The standards, Associating Six Sigma with client has 2nd precedence and Associating Six Sigma to concern scheme has last precedence as it got lowest weightage i.e. 0.1255.

Table 5.4 Average precedence and weightages for Six Sigma execution in car industry

Success Factors | Weights | Precedence | |

A | Education and preparation | 0.14316 | 5 |

Bacillus | Associating Six Sigma to concern scheme | 0.125535 | 6 |

C | Cultural Change | 0.15126 | 4 |

Calciferol | Associating Six Sigma to client | 0.1689 | 2 |

Tocopherol | Vision and program statement | 0.152485 | 3 |

F | Management engagement and committedness | 0.25866 | 1 |

5.1.5 Barriers for Six Sigma execution

Table 5.5 shows the barriers to the effectual execution of Six Sigma. The consequences of the analysis show that the six reacting companies felt merely fiscal restraint to be important at 0.1 degree of significance. This indicates the fact that it is easy to implement Six Sigma plan in the Indian car constituents sector, as merely one barrier is found to be important out of the eight.

Table 5.5Barriers for Six Sigma execution

Barriers | Mean | S.D. | t-value |

Fiscal Constraint | 3.33 | 0.52 | 1.58 |

Time Constraint, Difficulty in Understanding Complicated | 3.00 | 1.10 | 0.00 |

Statistical Tools | 3.00 | 1.10 | 0.00 |

Lack of Management Exposure | 2.00 | 1.10 | –2.24 |

Work Force/Union Resistance | 1.83 | 0.75 | –3.80 |

Improper Training | 1.83 | 0.75 | –3.80 |

Expensive Consultation Charges | 2.00 | 0.63 | –3.87 |

Trouble in Understanding Six Sigma Methodology | 1.83 | 0.41 | –7.00 |

5.1.6 Analysis of benefits with Six Sigma execution

Table 5.6: Benefits of Six Sigmaexecution

Benefits | Mean | S.D. | t-value |

Decrease in COPQ | 4.17 | 0.41 | 7.00 |

Increase in profitableness | 4.33 | 0.52 | 6.32 |

Improved merchandise quality | 3.83 | 0.41 | 5.00 |

Improved company image | 3.83 | 0.41 | 5.00 |

Decrease in procedure variableness | 4.00 | 0.63 | 3.87 |

Addition in productiveness | 4.00 | 0.63 | 3.87 |

Decrease in client ailments | 4.00 | 0.89 | 2.74 |

Decrease of rhythm clip | 3.83 | 1.17 | 1.75 |

Improved work civilization | 3.17 | 0.75 | 0.54 |

Improved employee morale/ motive | 3.00 | 0.63 | 0.00 |

Improved gross revenues | 2.33 | 0.52 | 3.16 |

Decrease in review | 2.33 | 0.52 | 3.16 |

Table 5.6 shows the assorted benefits of the Six Sigma plan The consequences of the analysis show that, in line with the Six Sigma doctrine of bottom line consequences, these Six Sigma companies have besides derived important fiscal benefits through reduced Cost of Poor Quality ( COPQ ) . Increase in profitableness, a 2nd important benefit, is a natural result of the decrease in COPQ.

5.1.7 Statistical analysis of CSFs for Six Sigma execution

Table 5.7: Critical success factors for Six Sigma

CSFs | Mean | S.D. | t-value |

Training | 4.67 | 0.52 | 7.91 |

Associating Six Sigma to clients | 4.67 | 0.52 | 7.91 |

Undertaking Prioritization and Selection | 4.67 | 0.52 | 7.91 |

Project Management Skills | 4.33 | 0.52 | 6.32 |

Cultural alteration | 3.83 | 0.41 | 5.00 |

Management Involvement and Participation ( Leadership ) | 4.00 | 0.63 | 3.87 |

Understanding of Six Sigma Methodology | 4.00 | 0.63 | 3.87 |

Associating Six Sigma to Business Strategy | 3.67 | 0.52 | 3.16 |

Organizational Infrastructure | 3.33 | 0.52 | 1.58 |

Associating Six Sigma to Employees | 3.17 | 0.41 | 1.00 |

Associating Six Sigma to Suppliers | 2.67 | 0.82 | 1.00 |

As shown in Table 5.7 preparation, associating Six Sigma to clients, undertaking prioritization and choice topped the list of CSFs, followed by undertaking direction accomplishments. Cultural alteration came following. Management engagement and engagement, and understanding Six Sigma methodological analysis stood at the 4th degree. Associating Six Sigma to concern scheme and organisational substructure are besides rated as important. Associating Six Sigma to employees and providers were rated as non important. This shows that companies have non linked their Six Sigma plan to their employees and providers.

5.1.8Comparison ofcritical successful factors analyzedwith literature

Table 5.8 Comparison of CSFsanalyzedwith literature

Factor | Present survey India | Previous Study ( Antonyet Al. , 2010 in UK ) |

Rank | Rank | |

Training | I | Six |

Associating Six Sigma to Customers | I | Two |

Undertaking Prioritization and Selection | I | Seven |

Project Management Skills | Four | Eight |

Cultural Change | Volt | Eight |

Management Involvement and Participation | Six | I |

Understanding of Six Sigma Methodology | Six | Volt |

Associating Six Sigma to Business Strategy | Eight | Three |

Organizational Infrastructure | Nine | Four |

Associating Six Sigma to Employees | Ten | Eleven |

Associating Six Sigma to Suppliers | Eleven | Ten |

These findings were rather contrary to the findings from the old surveies carried out by Antonyet Al. [ 51 ] in little and moderate-sized UK fabrication endeavors Results of that peculiar survey show that direction engagement and engagement, associating Six Sigma to clients and associating Six Sigma to the concern scheme of the organisation are the most of import factors for the successful execution of Six Sigma, followed by organisational substructure, apprehension of Six Sigma methodological analysis, developing on Six Sigma, and undertaking prioritization and choice. Table 5.8 gives the comparing of the present and old survey. This difference in the precedence attached to CSFs can be to due to the fact that India is a developing economic system and the industrial civilization and environment environing India are different from that of UK.

5.1.9 Model for Six Sigma execution

Six Sigma

Engagement of Employees | Organizational Infrastructure | Development of Teamwork | Focus on Customer | Focus on Supplier Relationship | Understanding of Six Sigma Methodology | Top direction committedness and leading | Associating Six Sigma to Customers | Quality Improvement Tools & A ; Techniques | Training and Education |

Figure 5.5 Model for Six Sigma execution

The top direction demands to be proactive in implementing Six Sigma and concentrate on incorporating Six Sigma with TS 16949. Associating Six Sigma plan to employees will assist in acquiring better cooperation, improved work civilization and morale. Associating Six Sigma to providers will assist in bettering coaction, which shall ensue in the effectual execution of Six Sigma. Organizations can derive much by volunteering to implement Six Sigma instead than waiting for it to be imposed. Evaluation and comparing of CSFs of Six Sigma aid organisations in the sector to attach the needed importance to assorted CSFs. Barriers of Six Sigma execution in Indian car constituents fabricating industries ISM modeling is performed. The consequences of ISM modeling shows Lack of Management Exposure and Expensive Consultation Charges are at first degree. The consequences of the Statistical analysis show that the companies felt merely fiscal restraint to be important at 0.1 degree of significance. This indicates the fact that it is easy to implement Six Sigma plan in the Indian car constituents sector, as merely one barrier is found to be important out of the eight. Harmonizing to the analysis, pillars of Six Sigma are arrived and general model for Six Sigma execution is developed. It is shown in figure 5.5.

The top direction demands to be proactive in implementing Six Sigma and concentrate on incorporating Six Sigma with TS 16949. Associating Six Sigma plan to employees will assist in acquiring better cooperation, improved work civilization and morale. Associating Six Sigma to providers will assist in bettering coaction, which shall ensue in the effectual execution of Six Sigma. Organizations can derive much by volunteering to implement Six Sigma instead than waiting for it to be imposed. Evaluation and comparing of CSFs of Six Sigma aid organisations in the sector to attach the needed importance to assorted CSFs. Barriers of Six Sigma execution in Indian car constituents fabricating industries ISM modeling is performed. The consequences of ISM modeling shows Lack of Management Exposure and Expensive Consultation Charges are at first degree. The consequences of the Statistical analysis show that the companies felt merely fiscal restraint to be important at 0.1 degree of significance. This indicates the fact that it is easy to implement Six Sigma plan in the Indian car constituents sector, as merely one barrier is found to be important out of the eight. Harmonizing to the analysis, pillars of Six Sigma are arrived and general model for Six Sigma execution is developed. It is shown in figure 5.5.